FARM PROCESSING

Javanese Coffee is dedicated to evolving and reviving the historical importance of Indonesian coffee and creating nothing less than a coffee revolution. In every aspect of coffee production whether it be growing, harvesting, processing or even delivery we question and challenge the status quo. Our goal is to achieve a vastly better product while building a sustainable and equitable model to support the future of coffee farms and farmers. With climate change threatening the entire coffee industry it is of paramount importance to draw upon the entirety of the coffee industry, scientific community, political leaders, and consumers to adapt and create solutions that will safeguard the future and quality of coffee.

Javanese Coffee was once a small Indonesian farm, but through shear will, determination and ingenuity has grown into a network of award winning farms; with importing operations in New York City, and distribution from our New Hampshire location throughout the entire East Coast.

As we have grown our scope of understanding from a local agrarian to a global commodity supplier we have come to recognize the lack of equity and support for the coffee farmer. This is severely compounded by the looming threat of climate change, and although many are actively pursuing future solutions the application of those solutions and immediate support of farmers has to happen in the present as they are suffering now. That is why Javanese Coffee has partnered with the nonprofit One Indonesian Coffee. One Indonesian Coffee is committed to directly supporting coffee farmers with real solutions now. through

Javanese Coffee aspires to guide and evolve not only the farm and farmers but the supply chain all the way to consumer. Only through such a holistic approach are we be able to evolve the quality and final product.

Our Certifications

Our partnering farms adhere to the following standards

FULLY WASHED

Fully washed processing often produces a brighter, cleaner flavor profile, with lighter body than natural process coffees or the honey process. Fully washed coffees are referred to also as washed coffees, or wet processed.

Note that the coffee seed is not fermented in this process, just the other fruit layer between the skin and the parchment shell. This is a natural action of peptic enzymes in the coffee

Picking

1. The dedicated farm workers at Javanese Coffee only pick cherries at their peak of ripeness and must return to the same tree repeatedly throughout the harvest time searching out the ripened cherries.

Pulping

2. Once the ripe cherries are picked the skin is removed with a pulper leaving only the mucilage.

Fermenting

3. The skinned cherries now enter a fermentation bath for about 12 hours and the remaining mucilage is removed leaving the parchment covered beans.

Drying

5. The parchment covered beans are dried until 11% moisture content, so the parchment is now loose around the green bean.

Sorting

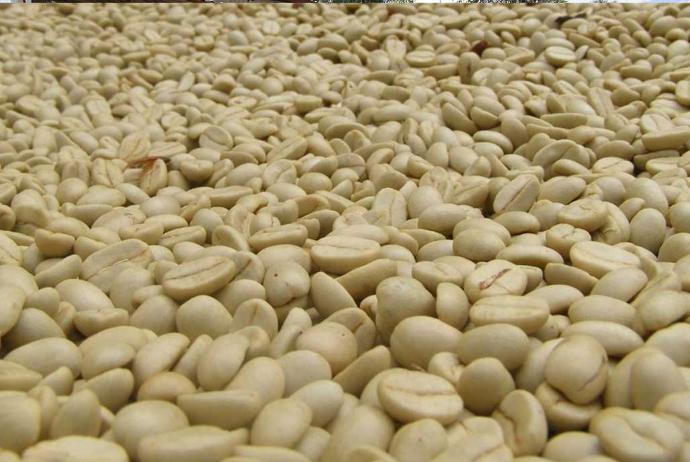

6. Finally the parchment is removed by a huller and the green bean is exposed and ready to move along to mechanical grading and manual hand sorting to separate out any undesirable beans and anomalies such as peaberries and the like.

Sorting

6. Finally the parchment is removed by a huller and the green bean is exposed and ready to move along to mechanical grading and manual hand sorting to separate out any undesirable beans and anomalies such as peaberries and the like.

HONEY PROCESS

Pulp natural coffees tend to have more body and less acidity than their fully washed process equivalents, and can have a cleaner, more uniform quality than natural process coffees.

This is This method is also called pulp natural.

Picking

1. The dedicated farm workers at Javanese Coffee only pick cherries at their peak of ripeness and must return to the same tree repeatedly throughout the harvest time searching out the ripened cherries.

Pulping

2. Once the ripe cherries are picked the skin is removed with a pulper leaving only the mucilage.

Drying

3. The drying process is one of the most difficult stages in the honey process and in any of the processes as it requires a skilled ability to dry the mucilage covered cherries to a moisture content of 14% through constant raking while keeping an eye on the weather and making sure the beans don’t ferment or grow bacteria. Once the beans have completed this stage they will be hulled removing the mucilage and parchment and the green beans are dried until they reach about 10% moisture content.

Sorting

1. The dedicated farm workers at Javanese Coffee only pick cherries at their peak of ripeness and must return to the same tree repeatedly throughout the harvest time searching out the ripened cherries.

Pulping

2. Once the ripe cherries are picked the skin is removed with a pulper leaving only the mucilage.

Drying

3. The drying process is one of the most difficult stages in the honey process and in any of the processes as it requires a skilled ability to dry the mucilage covered cherries to a moisture content of 14% through constant raking while keeping an eye on the weather and making sure the beans don’t ferment or grow bacteria. Once the beans have completed this stage they will be hulled removing the mucilage and parchment and the green beans are dried until they reach about 10% moisture content.

NATURAL PROCESS

Dry process coffees generally have more body and lower acidity than their wet process counterparts, with more rustic flavors due to the long contact between the drying fruit and the seed. They also can have more defects, taints, and lack of uniformity both in the roast and in cupping.

A natural process coffee is sometimes referred to as dry coffee, full natural, or traditional dry process, or abbreviated DP

Picking

1. The dedicated farm workers at Javanese Coffee only pick cherries at their peak of ripeness and must return to the same tree repeatedly throughout the harvest time searching out the ripened cherries.

Drying

3. After the cherries have been picked they must be dried to 14% moisture content. The natural process is unique to other processes as the cherries are dried without any skin or mucilage being removed. The whole cherry, including skin and mucilage as well as all the sugars within have time to affect the bean during the drying process. This is highly challenging as no fermenting or molding must occur and hence consistent and attentive raking must be used in drying houses to achieve a well dried cherry.

Sorting

6. Finally the parchment is removed by a huller and the green bean is exposed and ready to move along to mechanical grading and manual hand sorting to separate out any undesirable beans and anomalies such as peaberries and the like.

Picking

1. The dedicated farm workers at Javanese Coffee only pick cherries at their peak of ripeness and must return to the same tree repeatedly throughout the harvest time searching out the ripened cherries.

Pulping

2. Once the ripe cherries are picked the skin is removed with a pulper leaving only the mucilage.

Fermenting

3. The skinned cherries now enter a fermentation bath for about 12 hours and the remaining mucilage is removed leaving the parchment covered beans.

Washing

4. The fermented beans are thoroughly washed leaving the cleaned parchment covered beans. At this point all the mucilage has been removed off of the outer parchment layer.